Current Activities

EUROCORR 2026

6 - 10 September 2026, Dublin, Ireland

Announcement of WP Session on Corrosion Reliability of Electronics

This WP session aims to provide a common platform for extended discussion on corrosion issues of electronics and associated functional issues in low- and high-power electronics. WP23 sessionat EUROCORR 2026, Dublin, will focus on following topics, but not limited to:

- Corrosion failure modes and mechanisms: Low power and high power

- Effect of high voltage and high power on failure modes and mechanism

- Synergistic effects of humidity and gases on power electronics failure

- Corrosion issues of power electronics components such as IGBTs

- Application sectors and issues: Wind Energy, Solar Energy, E-mobility.

- Process cleanliness aspects in relation to humidity effects

- Conformal coatings for corrosion protection

- Better packaging for humidity robustness and humidity modelling

- Gaseous corrosion issues of electronic components

- Corrosion of electrical contacts and connectors

In 2026, the Zestron Best Paper Presentation Award for Junior Researchers will be presented for the second time (first award winner see below). It is aimed for junior researchers (PhD and postdoctoral students) presenting a paper in this session.

All junior researchers are encouraged to submit abstracts.

The call for papers will open in November. Deadline for abstract submission: 16 January 2026

We are looking forward to your participation in EUROCORR 2026.

WP 23 Award

Initiated by Rajan Ambat, Chair of WP23, this year's WP23 session at EUROCORR 2025 featured a “ZESTRON Best Paper Presentation Award for Junior Researchers,” which is aimed at PhD and postdoctoral students.

The 2025 Award was presented to

Florian Georges

France

(in absence) at the closing session of EUROCORR 2025 for his excellent presentation "Study of halide contamination on the corrosion behavior of materials for microelectronic applications".

The winner receives a certificate and a cash prize of 500 EUR. The handover of the certificate will take place at the earliest convenience.

The award is generously sponsored by ZESTRON

About Zestron: For over 30 years, ZESTRON has been supporting its customers in making manufacturing processes more robust, increasing product reliability, and maximizing yield – for both assembled PCBs and Power Electronics.

Photo caption: Dr. Markus Meier, Zestron, presenting the certificate to the audience (photo: Kristina Maria Lagahino Erland)

Business Meeting

Next Business Meeting at the upcoming EUROCORR

Knowledge transfer

Due to the interdisciplinary nature of the subject, the knowledge sharing between various actors is an important part of the WP net-working activity. Organization of workshops, seminars, and symposia with respect to the basic understanding and industrial application will be part of this strategy.

Main interests for the Working Party, but not limited to are:

- Electrochemistry under thin water layers and reliability of electronics

- Corrosion failure modes and mechanisms related to electronics

- Process cleanliness, design aspects, and interaction with humidity

- Corrosion mitigation strategies and early prediction for electronics

- Testing methods and standards useful for humidity effects

- Specific corrosion issues related to material in electronics and components

- Importance of enclosure design and various levels of packaging

And prospective industrial sectors for the Working Party include:

- Power electronics and control systems

- Electronics for offshore applications

- Electronics for energy systems

- Automotive electronics

- Aerospace electronics

- Consumer electronics

- Medical electronics

Get involved!

If you wish get involved with EFC and the activities of the Working Party please click here to register!

Mission

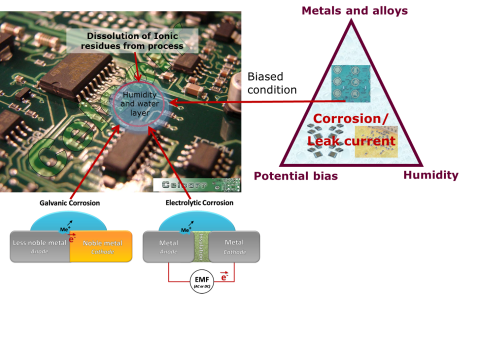

Electronic devices, components, and products world-wide today face corrosion reliability issues resulting in premature fault and intermittent or permanent failures due to humidity exposure. The humidity related functionality issues and corrosion problems compromise the durability and reliability of the devices resulting in huge economic loss. Often a faulty signal or erroneous function by an electronic device is linked to the water layer formation on the surface of the printed circuit board assembly (PCBA) resulting from the humidity exposure and the water layer acting as electrolyte for electrochemical processes. Problem is compounded today due to a number of factors specific to the electronic devices such as miniaturization, high level of integration, and multi-material usage on the PCBA. These factors together with the applied potential bias when the device is working and contamination introduced during the manufacturing process causes a number of humidity related failure modes in electronics. Today electronic devices and control systems are part of almost all installations exposing them to all climatic conditions from clean room to severe offshore conditions.

Corrosion failure modes under humidity exposure conditions includes: leak current failures due to surface insulation reduction, electrochemical migration, galvanic corrosion due to micro-galvanic cell formation, creep corrosion, and corrosion caused by gaseous environment. Leak current and electrochemical migration issues are of particular importance due to the possibility of intermittent or permanent electrical functionalities issues causing device breakdown.

Both industrial electronics and consumer electronics suffer from corrosion reliability issues and the exposure conditions vary from humid to harsh environments. Therefore, incorporating enhanced corrosion performance in the design is relevant for all, which needs collaborative effort between interdisciplinary areas namely electronics, electrical, and corrosion specialists enabling remedial measures based on proper understanding of corrosion and electrochemical mechanisms.

The vision of this Working Party is to build the necessary interdisciplinary understanding required for solving the corrosion reliability issues at European level merging the expertise of various actors and to identify the industrial, and research and development needs, share knowledge and ideas, and develop information net-work at international level.

Research and development

This Working Party activity focus on understanding the root cause for humidity related failures based on corrosion and electrochemical mechanisms combined with electronics and electrical aspects. Improved understanding will be useful for developing mitigation strategies and predictive tools for PCBA and device design at various levels. Working Party also focus on sharing and comparing information on various test methods and methodologies used for analysis.

Publications

Information Resources

Journal publications, CELCORR group

(http://www.celcorr.com/index.php/publications/journal-publications)

Conference publications, CELCORR group

(http://www.celcorr.com/index.php/publications/conference-proceedings)

ZESTRON Best Paper Presentation Award for Junior Researchers

Initiated by Rajan Ambat, Chair of WP23, in 2025, the WP23 session at EUROCORR features a “ZESTRON Best Paper Presentation Award for Junior Researchers,” which is aimed at PhD and postdoctoral students.

The award comprises a certificate and a cash prize of 500 EUR and is generously sponsored by ZESTRON.

About Zestron:

For over 30 years, ZESTRON has been supporting its customers in making manufacturing processes more robust, increasing product reliability, and maximizing yield – for both assembled PCBs and Power Electronics.

Award winners

2025

The 2025 ZESTRON Best Paper Presentation Award for Junior Researchers was presented to

Florian Georges

INSA Lyon, France

for his excellent presentation "Study of halide contamination on the corrosion behavior of materials for microelectronic applications".

Previous Activities

Workshops

Workshop on Corrosion reliability of electronics, Eurocorr 2014, 8-12 September 2014, Pisa, Italy

Workshop on Corrosion reliability of electronics, Eurocorr 2015, 6-10 September 2015, Graz, Austria

Training of GfKORR guide line for the application of protective coating of electronic assemblies Ingolstadt, Germany, 2018 November 21st and 22nd

Workshop on "Corrosion reliability of electronics devices" as part of the EUROCORR 2018, 9-13 September 2018, Krakow, Poland

3rd Seminar on Climatic reliability of electronics: Global perspectives and challenges, 30-31 January 2018, DTU, Lyngby, Denmark

10th International Seminar on Climatic Reliability of Electronics - Challenges and Perspectives, 3-4 April 2025, Lyngby, Denmark (EFC Event No.529)

Sessions at EUROCORR

WP Session on Corrosion Reliability of Electronics at EUROCORR 2025, 7-11 September 2025, Stavanger, Norway

Working Party meeting presentation/minutes

Task Group meeting, Eurocorr 2016, Montpellier, France

Working Party meeting, Eurocorr 2017, Prague, Czech Republic

Members area

The following pages are restricted to members of the EFC Working Party (EFC Task Force).

EFC is working with the DECHEMA Community-Tool. If you attended former events of the EFC (e.g. EUROCORR) or DECHEMA, your address may be registered already. Please fill in these login details below.

Forgot your password? Please click here to reset your password.

If you don't have an account, please register here.